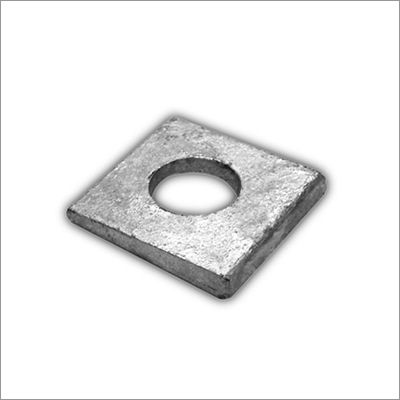

Tapper Washer

MOQ : 5000 Pieces

Tapper Washer Specification

- Finish

- Smooth

- Load Capacity

- Heavy Duty

- Material

- Mild Steel

- Shape

- Tapered / Conical

- Thickness

- 3mm 20mm

- Surface Treatment

- Hot Dip Galvanized / Black Finish

- Standard

- IS 5372 / DIN 434 / Customized

- Application

- Used for Channel/Beam Mounting in Electrical, Railway, and Construction Industries

Tapper Washer Trade Information

- Minimum Order Quantity

- 5000 Pieces

- Supply Ability

- 100000 Pieces Per Week

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Main Domestic Market

- All India

About Tapper Washer

With our enriching expertise in this sector, we have been able to manufacture and supply a huge stock of Taper Washer. Our offered washer provides the required arrangement for controlled and continuous flow of liquid to or from the pipeline. We make available these washers to our variegated clients in different sizes and diameters. This Taper Washer is made using stainless steel, which is procured from the authentic sources of the market.

Features:

- Coated with non-corrosive material

- Excellent impact strength

- Smooth edges

Precision Alignment and Vibration Dampening

Tapper Washers are designed to ensure accurate structural alignment and to absorb vibration. Their conical shape makes them ideal for distributing load evenly across surfaces, particularly in channel and beam mounting tasks where stability is crucial.

Durability for Demanding Environments

Constructed with mild steel and treated for enhanced corrosion resistance, these washers withstand harsh environments typical of electrical substations, railway infrastructure, and construction sites. The robust hardness and heavy-duty design ensure long service life and reliability.

Versatile Packaging and Finish Options

You can choose from gunny bag or box packaging based on your logistics preferences. Finishes in silver (galvanized) or black (coated) give flexibility for aesthetic and functional requirements. Custom sizing and standards ensure seamless integration into diverse industrial applications.

FAQs of Tapper Washer:

Q: How should Tapper Washers be used for structural alignment and vibration absorption?

A: Tapper Washers should be placed between the mounting surfaces of channels or beams and the fasteners to compensate for misalignments and absorb vibration. Their tapered design helps distribute load evenly, enhancing stability in structural installations.Q: What standards do these Tapper Washers comply with?

A: These washers adhere to IS 5372 and DIN 434 standards for quality and dimensions. Customized standards can also be accommodated based on project requirements.Q: When is it advisable to use a hot dip galvanized finish over a black finish?

A: A hot dip galvanized finish is recommended for outdoor or corrosive environments due to its superior corrosion resistance. The black finish is suitable for indoor applications or where aesthetic consistency with other black hardware is needed.Q: Where are these Tapper Washers commonly applied?

A: They are widely utilized in structural mounting tasks within the electrical, railway, and construction industriesprimarily for channel and beam mounting, where precise alignment and vibration absorption are crucial.Q: What is the manufacturing process for these washers?

A: The washers are manufactured from mild steel, cut and formed into a tapered or conical shape according to IS 5372 or DIN 434 standards. They are then finished with hot dip galvanization or black coating for corrosion resistance, and checked for tolerance, hardness, and finish quality.Q: What are the main benefits of choosing these Tapper Washers for heavy-duty applications?

A: Benefits include high load-bearing capacity, excellent corrosion resistance, superior vibration absorption, and precise alignment capabilities, making them ideal for demanding industrial uses.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS